Call Us +44 (0)1686 611200

Proudly Made in the United Kingdom

Construction Sites: Which 5 Forklift Attachments are Best ?

September 29, 2021

Construction equipment can be large and place certain limitations on the type of work that can be performed. Forklift attachments can prove a valuable piece of kit and enable you to transform your forklift as and when you need a specific task done. In this article we explain the five most popular models for the construction industry.

Introduction to Forklift Attachments

All forklift attachments are designed to make the process of material handling safer, easier, and quicker. With the construction industry particularly making use of the diverse range of attachments available — from drum handling to lifting and personnel at height working — forklifts can be easily converted into equipment needed for a specific task.

Fitted to the forks of a forklift truck or telehandler, or to the forklift carriage and telehandler quick hitch, attachments can offer versatility to forklifts and telehandlers way beyond their original intended usage as a ‘lifting’ machine.

In construction, the most popular forklift attachments include:

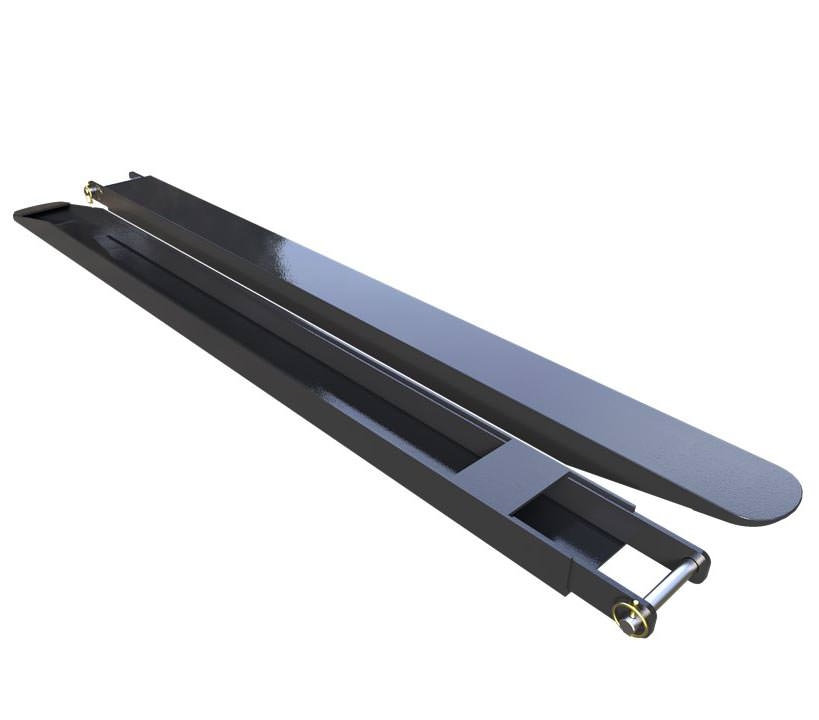

Fork Extensions

When long, potentially unstable loads need to be handled, fork extensions provide an invaluable piece of equipment and simply slip over the existing forklift tines of your forklift truck or telehandler.

When long, potentially unstable loads need to be handled, fork extensions provide an invaluable piece of equipment and simply slip over the existing forklift tines of your forklift truck or telehandler.

The temporary fit nature of forklift extension sleeves can negate the need to purchase a longer pair of forklift tines or a new piece of machinery altogether — providing a cost-effective solution for your existing equipment which can be used, and removed, as you need.

Fork tine extensions, available in a range of lengths to suit all different sizes of forks, are simply slipped over the existing forks and secured in place via a heel pin retention. Like all attachments, they need to be used correctly and not misused, with careful consideration being made to how the load is dispersed across the extension length. For more detail information about forklift extensions and how to use them correct, check out “What Forklift Truck Drivers Need to Know about Fork Extensions".

With construction and building sites frequently moving products around the site, fork extensions can be a very useful attachment when the load is too long for the conventional forks fitted to your forklift truck.

Forklift Tipping Skips & Bins

One of the most popular forklift attachments on the market for a wide variety of industries, forklift tipping skips — which can also be fitted to telehandlers — provide an efficient way of collecting and removing rubble and waste from the construction site.

One of the most popular forklift attachments on the market for a wide variety of industries, forklift tipping skips — which can also be fitted to telehandlers — provide an efficient way of collecting and removing rubble and waste from the construction site.

Strategically placed around the construction site, tipping skips and tipping bins can be used for collecting all manner of debris and once full, can be simply transported and tipped into the nearest waste collection point.

With mechanical operation, tipping skips are easily tipped once full by means of a pull release handle, which when activated allows the bin to roll forward and empty. Many designs of tipping skips allow for the bin to also return back to its original position and lock back in place ready for the next load.

At construction sites, it’s generally common practice to use heavy-duty tipping skips (manufactured from 5mm/6mm thick steel) due to the arduous environment that they operate in. However, regular duty tipping skips (manufactured from 3mm thick steel) can also be used depending on the type of waste being collected.

Available in a wide range of sizes, with the 1.2m3 capacity proving most popular for use on building and construction sites, there are a range of tipping skips available to suit your requirements — some with lids and auto release skips which allow the operator to tip the skip without having to leave the seat of the cab.

For applications in environment and recycling settings, tipping skips can also be supplied in various colours for colour coding — helping you to recycle and dispose of waste safely and efficiently.

Forklift Sweepers

From Push Broom forklift sweepers, to powerful hydraulic rotary sweepers, there is a wide range of sweeper accessories to choose from.

From Push Broom forklift sweepers, to powerful hydraulic rotary sweepers, there is a wide range of sweeper accessories to choose from.

Push broom sweepers, fitted to the tines of the forklift or telehandler provide a simple yet effective method of free sweeping and can be a useful attachment when the building or construction site needs a quick clean up.

Using the forward motion of the forklift truck, building sites can be swept clean via the Polypropylene bristles, which can be replaced to give the sweeper an extended service life. Push broom sweepers such as these can make labour-intensive sweeping a thing of the past.

For larger areas, more powerful sweeping equipment — such as the hydraulic rotary sweeper — can provide a perfect solution. Available in different models to suit indoor or outdoor applications, these versatile sweepers, once connected to the hydraulics of the truck, can convert your forklift or telehandler into an instant powerful sweeping machine for larger surface areas.

For larger areas, more powerful sweeping equipment — such as the hydraulic rotary sweeper — can provide a perfect solution. Available in different models to suit indoor or outdoor applications, these versatile sweepers, once connected to the hydraulics of the truck, can convert your forklift or telehandler into an instant powerful sweeping machine for larger surface areas.

They also incorporate large rotary brushes and can come with its own collection hopper to allow waste and debris to be collected at the same time and emptied easily.

Building and construction sites can be swept and cleared in no time through use of a hydraulic rotary forklift sweeper, and if dust is a problem, sweepers can also come supplied with their own water tanks and water spray systems.

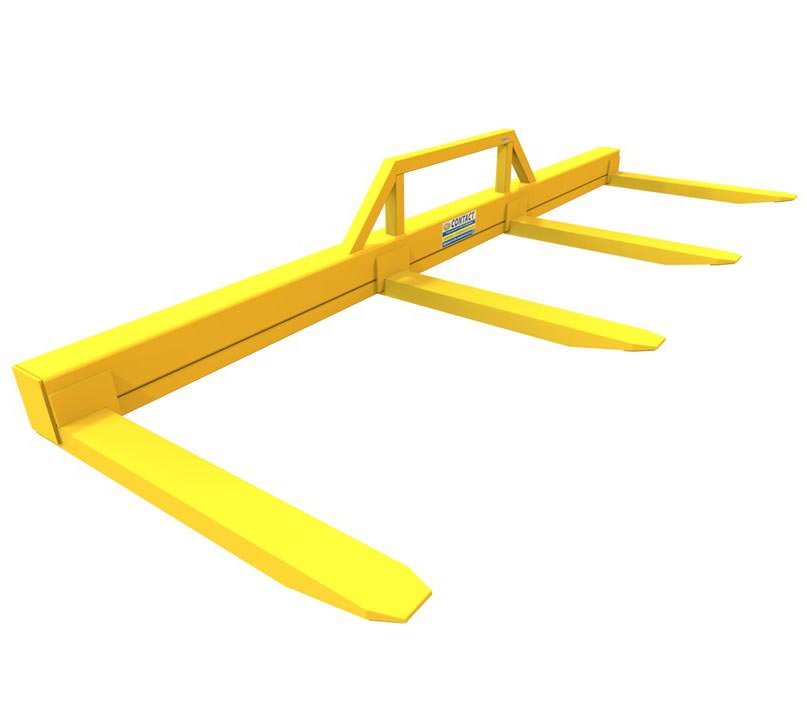

Wide Load Stabilizers/Four Fork Attachments

When it comes to handling wide or awkward loads such as sheets of plasterboard, roofing beams, or pipes around the construction or building site, wide load stabilising attachments is the accessory of choice.

When it comes to handling wide or awkward loads such as sheets of plasterboard, roofing beams, or pipes around the construction or building site, wide load stabilising attachments is the accessory of choice.

The Four Fork attachment utilises the two inner sleeves of the existing forks of the forklift or telehandler, and spreads the weight across all four fork sleeves, providing added stability and support.

With product damage being a common problem when it comes to handling fragile building products due to either excessive bouncing or bowing on the forks during transport, Four Fork attachments can go a long way in helping to mitigate these unwanted handling costs.

Also available in an ‘Adjustable’ design, where the two outer fork sleeves can be adjusted laterally, these particular Four Fork Attachments can handle a wider range of product widths, making them a very adaptable piece of equipment for any building or construction site.

Lifting Hooks & Yokes

One of the simplest and most effective attachments on the construction site, forklift hook attachments (also sometimes referred to as ‘Yokes’) are simply fitted over the existing forks of the forklift or telehandler allowing the load to hang underneath. With the forklift hook attachment able to fit anywhere along the fork blade length (avoiding the tip area) the attachment is then secured to the forks via T screw retention.

One of the simplest and most effective attachments on the construction site, forklift hook attachments (also sometimes referred to as ‘Yokes’) are simply fitted over the existing forks of the forklift or telehandler allowing the load to hang underneath. With the forklift hook attachment able to fit anywhere along the fork blade length (avoiding the tip area) the attachment is then secured to the forks via T screw retention.

For more dedicated lifting or where there is potential for a ‘swinging’ load and movement of the attachment, then the forklift hook attachment can also come in a ‘fixed length’ design, which calls for the attachment being secured to the back of the forks via heel bar retention. Fixed lengths are available in a range of distance (500mm to 900mm) to best suit the requirements of the task in hand.

By fitting a forklift hook attachment, your forklift or telehandler can be transformed into a mobile crane in a matter of minutes, which can come in handy around the building or construction site when heavy objects need to be lifted and moved.

Construction Sites Are Just One Place Where Forklift Attachments Are Useful

There are many more attachments that are used and suitable for use on construction and building sites, such as scissor brick grabs, forklift magnets, and crane lifting jibs to name but a few.

If you would like to know what attachments are available for your particular industry, from construction and manufacturing, to food and drink, please do get in touch with a member of the team today.