Call Us +44 (0)1686 611200

Proudly Made in the United Kingdom

An Easy Guide To The Different Types Of Forklift Lifting Attachments

October 26, 2021

Lifting attachments for forklifts are designed to help operators safely lift, carry, or convey loads. In this short guide, we discuss some of the different products available (and their uses), as well as the pros and cons of each.

Forklift Crane Jib Attachments

Available in a range of configurations, forklift crane jib attachments can come fitted either to the forks themselves (fork-mounted) or fixed directly to the forklift carriage (carriage-mounted).

Available in a range of configurations, forklift crane jib attachments can come fitted either to the forks themselves (fork-mounted) or fixed directly to the forklift carriage (carriage-mounted).

Both fixed and telescopic beams are available. The telescopic beams have inner beams which can be manually extended, increasing the overall length of the crane jib, usually up to 3 metres.

Forklift crane jibs can have multiple hook positions for added lifting versatility, although careful consideration needs to be made to ensure the combined weight of the lifting jib, product weight, and lifting reach, is within the capabilities of the forklift truck.

Forklift Fork Extensions

Designed to slip over the existing forks of the forklift truck, these extensions are an excellent, and in most cases, cheaper, an alternative to longer forklift forks. Fitting longer forks is not always a viable option due to associated issues with truck maneuverability.

Designed to slip over the existing forks of the forklift truck, these extensions are an excellent, and in most cases, cheaper, an alternative to longer forklift forks. Fitting longer forks is not always a viable option due to associated issues with truck maneuverability.

When a temporary solution is needed to handle a long or awkward load, forklift extensions prove an invaluable piece of material handling equipment and are used in various industries on a daily basis. For more information on forklift extensions and how they are used, do check out our “What Forklift Truck Drivers Need to Know about Fork Extensions" guide.

Forklift Spreader Beams

Like extensions, forklift spreader beams can be fitted directly to the forklift forks (fork-mounted) or slung from an overhead hook (crane slung). They offer a safe and practical solution to handling long or wide loads using a forklift truck.

Like extensions, forklift spreader beams can be fitted directly to the forklift forks (fork-mounted) or slung from an overhead hook (crane slung). They offer a safe and practical solution to handling long or wide loads using a forklift truck.

With hooks and slings generally situated at each end, wide loads can be lifted in a stable position thus removing the dangerous ‘swinging’ action.

Forklift spreader beams can be manufactured in a wide range of widths and lifting capacities, providing you with a suitable option based on your exact needs.

Forklift Wide Load / Four Fork Attachments

When it comes to handling wide loads with support underneath, the Four Fork attachment is an accessory of choice. With four fork sleeves, and the two inner sleeves utilising the forklift forks, wide loads can be fully supported from below eliminating the ‘bouncing’ or ‘bowing’ effect that can often occur when these types of products are transported on forklift forks alone.

When it comes to handling wide loads with support underneath, the Four Fork attachment is an accessory of choice. With four fork sleeves, and the two inner sleeves utilising the forklift forks, wide loads can be fully supported from below eliminating the ‘bouncing’ or ‘bowing’ effect that can often occur when these types of products are transported on forklift forks alone.

Subsequent product damage and associated handling costs can also be avoided when handling wide products of a fragile nature, through the use of a Four Fork Attachment.

Forklift Booms

The forklift boom was initially designed for handling lifting and transporting any rolled products such as carpets, coils, turf, paper — things that need to be supported through the length of its core. Although it has other uses too, the boom is the ideal product of choice when handling rolled and longer items. A quick and sturdy solution, the boom can be quickly fitted to the forks and where a more permanent fixture is required, the carriage-mounted boom is the perfect choice.

The forklift boom was initially designed for handling lifting and transporting any rolled products such as carpets, coils, turf, paper — things that need to be supported through the length of its core. Although it has other uses too, the boom is the ideal product of choice when handling rolled and longer items. A quick and sturdy solution, the boom can be quickly fitted to the forks and where a more permanent fixture is required, the carriage-mounted boom is the perfect choice.

Forklift Safety Platforms

Lifting people with a forklift truck, rather than lifting an object, is easy using the forklift safety platform. Whether the task at hand is of an emergency or non-routine nature (such as carrying out immediate urgent repairs to a building structure, or replacing overhead lighting), these platforms prove a cheaper alternative to hiring dedicated lifting machinery.

Lifting people with a forklift truck, rather than lifting an object, is easy using the forklift safety platform. Whether the task at hand is of an emergency or non-routine nature (such as carrying out immediate urgent repairs to a building structure, or replacing overhead lighting), these platforms prove a cheaper alternative to hiring dedicated lifting machinery.

For more information on forklift safety platforms and their uses, check out “Your Complete Guide to Forklift Safety Cages” blog.

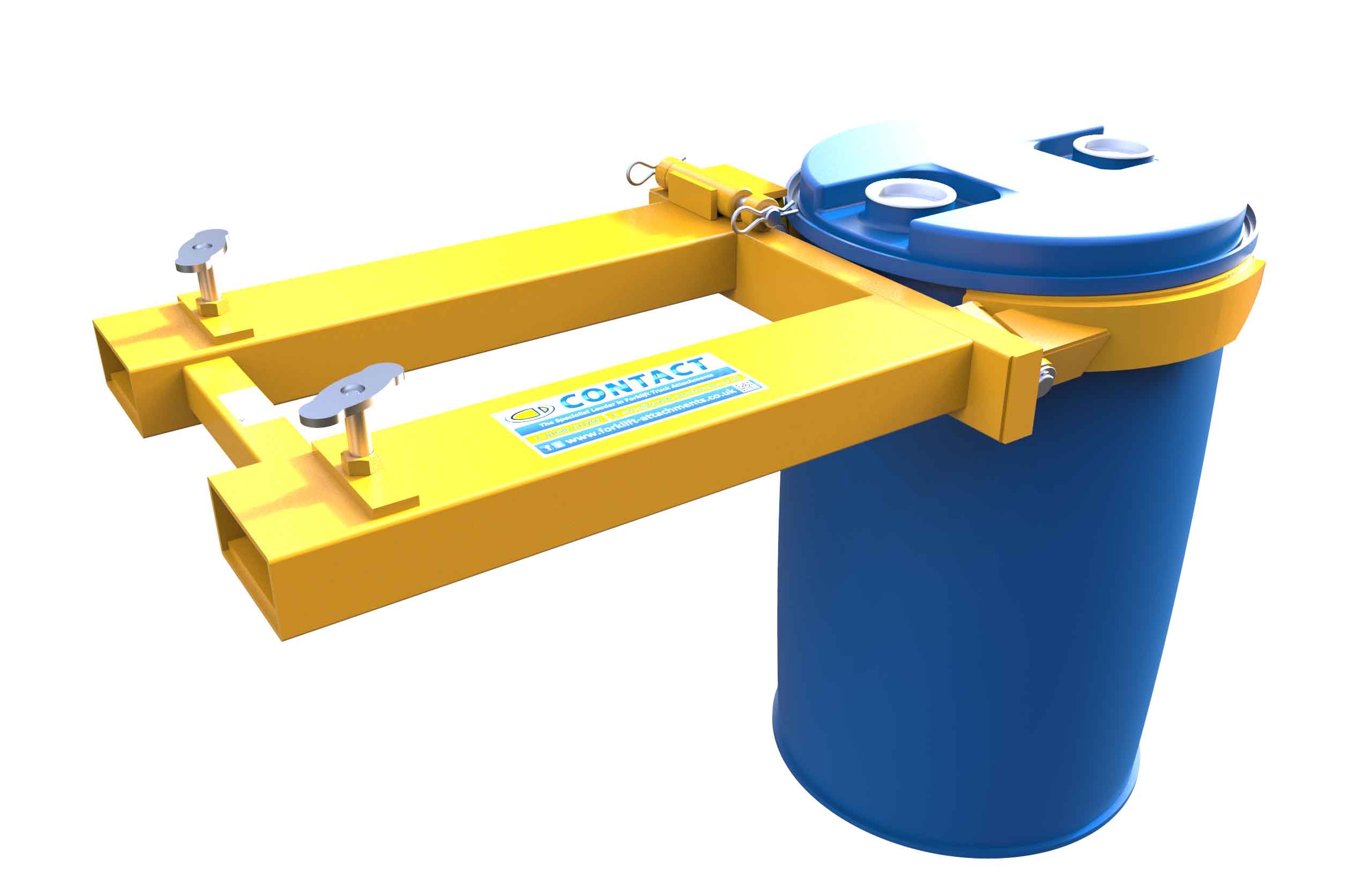

Forklift Drum Lifters

Drums come in all shapes and sizes, which is why you’ll find a wide array of forklift drum lifters available on the market.

Drums come in all shapes and sizes, which is why you’ll find a wide array of forklift drum lifters available on the market.

Some lifters are specifically designed for handling steel drums with ‘rolling hoops’, whilst others can handle both plastic and steel.

If the drums are packed tightly together, such as on a pallet, there are products with grippers designed to grasp the drum around its lip, as well as hydraulic grabs designed to fit a wide range of diameters and drum types.

Specialised handling equipment is also available specifically designed to handle irregularly ‘egg-shaped’ Mauser drums.

For a full rundown on forklift drum handling equipment, do read our guide to “Picking the Perfect Drum Handling Attachment”.

Conclusion

With so many different models and types of lifting attachments on the market, each designed to help with specific manual handling requirements, it can be tricky to know which one you need.

If you have any questions or would like to speak to a member of our expert design, technical, or manufacturing team, please do contact us using the ‘chat’ button, or call us on 0800 028 3332.