Call Us +44 (0)1686 611200

Proudly Made in the United Kingdom

5 Useful Attachments That Can Prevent Forklift Forks From Damaging Your Products

March 02, 2022

Are your products being damaged by forklift forks? Learn how to protect your products from damage using one of these effective forklift attachments and increase the efficiency of your forklift operators at the same time

The problem with forklift handling

Whilst forklift trucks are the ultimate machine when it comes to material handling, there are many issues that can arise when handling products of a fragile nature via the forks.

- The fork punctures the product

If the forklift forks are not set at the appropriate distance apart or aren’t correctly aligned to suit the product that is being handled, there is risk that the tips of the forks could puncture the product

- The product slips off the forks

Forklift forks are not really designed to handle products of a cylindrical nature, and in doing so, the risk of the product rolling off the forks is high. Slippery products can also easily slide off wet forks without due care and attention

- The product is pressed too hard against the fork upright

Whilst it is best practice to handle the load as close to the forklift as possible, this can sometimes cause damage to the product if the item being handled is pressed up against or rubs against the upright of the forklift forks

- The product is too fragile for the steel fork

Sometimes the steel material of the fork is just too harsh for a fragile product and without adequate protection from the steel contact of the fork, the product can become damaged

5 Useful Attachments To Help Prevent Fork Product Damage

Once the load is on the forklift, how to protect your product from damage should be taken into consideration. Here’s five useful forklift attachments that have been specifically designed to protect the load during handling, loading, and transportation of goods

(1) Fork Protection Sleeves

Fork Protection Sleeves are a metal fabricated sleeve that slips over the existing forks, and come coated with a durable Polyurethane coating which removes any contact between the steel and the forks when handling products. To further increase the protection of the load being handled, rubber crumb can be added to the Polyurethane coating for added anti-slip properties

Fork Protection Sleeves are a metal fabricated sleeve that slips over the existing forks, and come coated with a durable Polyurethane coating which removes any contact between the steel and the forks when handling products. To further increase the protection of the load being handled, rubber crumb can be added to the Polyurethane coating for added anti-slip properties

(2) Magnetic Fork Covers

An effective solution to prevent product damage when using forklift forks are the Magnetic Fork Covers. The magnetic covers come with a durable ‘ribbed’ designed with a rubber top surface to protect the load from the steel of the forks, whilst adding friction for any slippery loads that may be handled. As the name suggests, the magnetic fork covers have a magnetic underside which securely adheres to the forklift forks

An effective solution to prevent product damage when using forklift forks are the Magnetic Fork Covers. The magnetic covers come with a durable ‘ribbed’ designed with a rubber top surface to protect the load from the steel of the forks, whilst adding friction for any slippery loads that may be handled. As the name suggests, the magnetic fork covers have a magnetic underside which securely adheres to the forklift forks

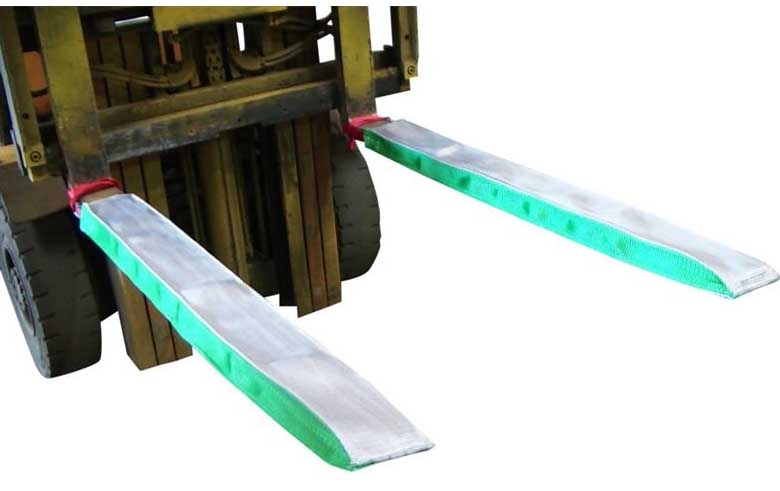

(3) Fabric Fork Shoe Sleeves

For a low-cost yet effective method of fork protection, the Fabric Fork Shoe Sleeves are a worthy investment. Suitable for use with lightweight product handling, the Fabric Fork Sleeves are produced from heavy duty woven Polyester, and slip over the forks just like a sock. They are especially useful to protect products from scratching or marks as a result of handling, loading, or transportation

For a low-cost yet effective method of fork protection, the Fabric Fork Shoe Sleeves are a worthy investment. Suitable for use with lightweight product handling, the Fabric Fork Sleeves are produced from heavy duty woven Polyester, and slip over the forks just like a sock. They are especially useful to protect products from scratching or marks as a result of handling, loading, or transportation

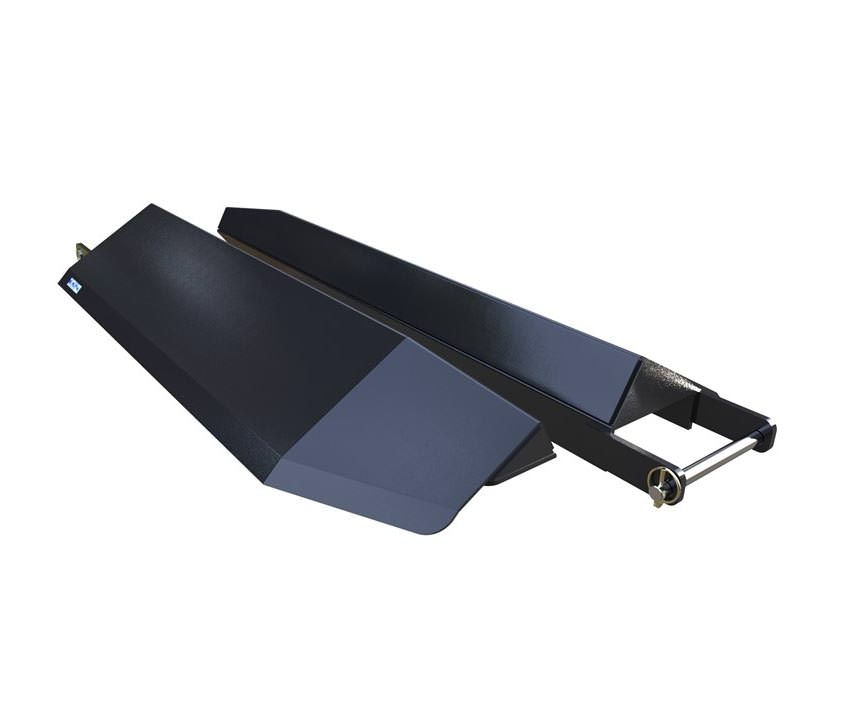

(4) Triangular Fork Sleeves

For handling rolled products (such as paper reels)on the forklift forks, these Triangular Fork Sleeves, which have an angled face, are designed to allow the cylindrical object being handled to sit in the ‘V’ recess that is created by these fork sleeves. This, in turn ensures the product being handled cannot roll of the forks.

For handling rolled products (such as paper reels)on the forklift forks, these Triangular Fork Sleeves, which have an angled face, are designed to allow the cylindrical object being handled to sit in the ‘V’ recess that is created by these fork sleeves. This, in turn ensures the product being handled cannot roll of the forks.

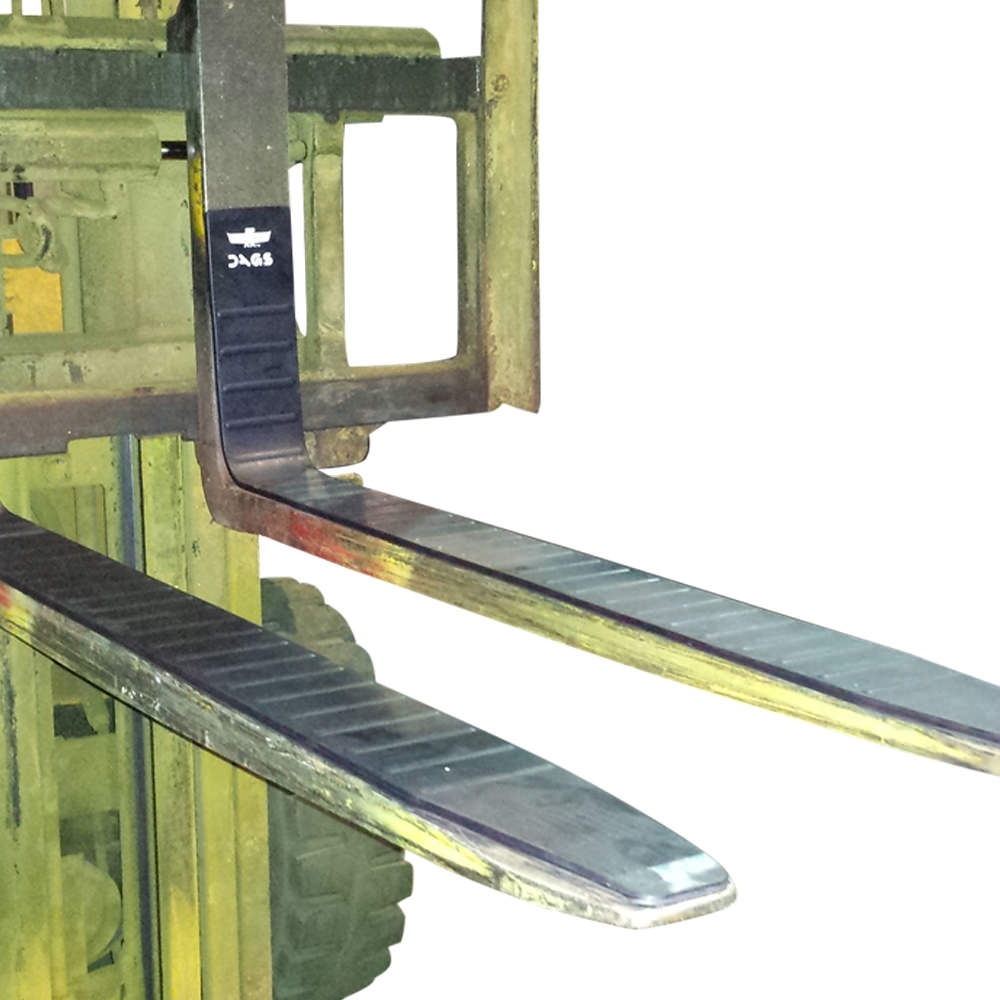

(5) Fork Load Protection Buffers

Commonly, damage to the product being handled on the forklift forks can be caused by the product rubbing against the upright of the forklift fork. These Fork Protection Buffers offer a solution by providing a rubber cushioned barrier between the product and the upright of the fork. By simply fitting over the fork upright (also known as the fork ‘shank’), your load can be protected by this useful forklift accessory

Commonly, damage to the product being handled on the forklift forks can be caused by the product rubbing against the upright of the forklift fork. These Fork Protection Buffers offer a solution by providing a rubber cushioned barrier between the product and the upright of the fork. By simply fitting over the fork upright (also known as the fork ‘shank’), your load can be protected by this useful forklift accessory

Conclusion

Whatever type of product you’re handling and for whom, any damage caused during the handling, loading, and transportation process can be costly. These simple yet effective accessories have been purposely designed to reduce the risk of products being damaged during this process, and many offer added safety and stability advantages. A win:win for any company who regularly uses the forklift’s forks to handle products, particularly those of a costly, fragile, or delicate nature.